Products

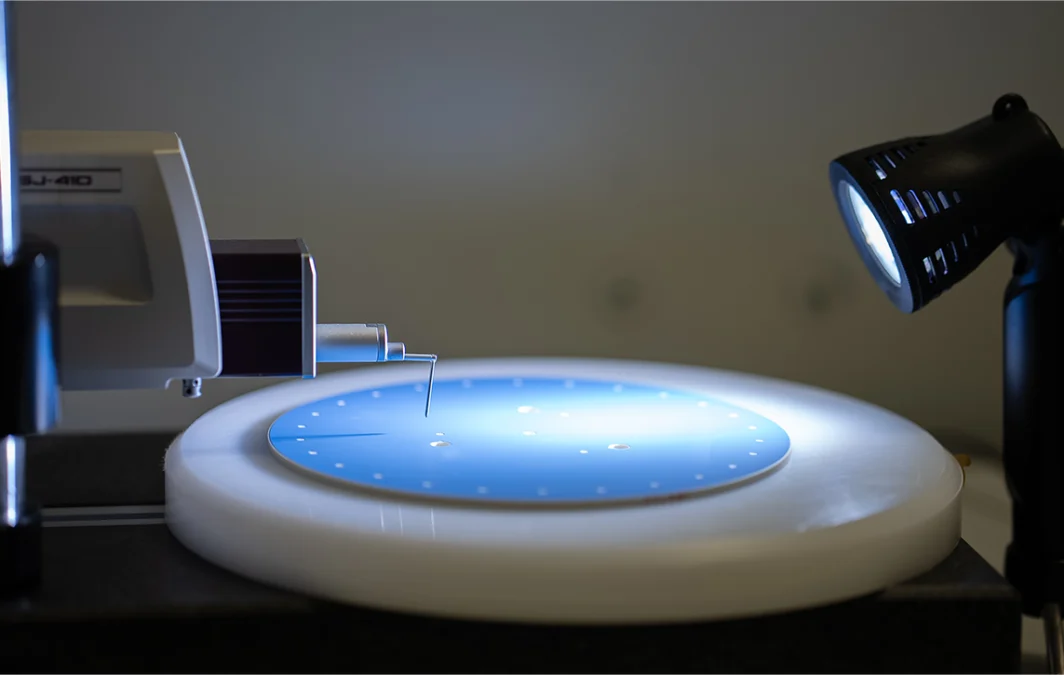

Electrostatic Chucks (ESC)

SEMCO Technologies’ eChuck offer smart solutions for the clamping and processing of all types of wafers. With more than 30 years of expertise and know-how, SEMCO Technologies has a team of engineers dedicated to innovation in the field of PVD, CVD, ion implantation, etching, inspection and handling.

SEMCO Technologies, expert in electrostatic chucks

Discover our eChucks

SEMCO Technologies has been designing and manufacturing in France innovative electrostatic chucks (ESC) and heating pedestals for the wafer processing industry since 1992.

SEMCO Technologies provides leading OEMs, Semiconductor Fabs, foundries and laboratories worldwide, directly, or through SEMCO Technologies subsidiaries and service centers.

About our chucks

Technical

Characteristics.

Unique solution integrated in one chuck including clamping BSG gas management heaters and temperature measurement.

Safe and easy handling of semiconductor wafers, flat panel displays, solar cells, etc. Clamping capability of a variety of materials including dielectrics and compounds.

Size

Compatible with substrates from 50-mm to 450-mm diameter.

Process Temperature

Wide operating temperature range between -150°C (-238°F) and +650°C (+1200°F).

Coulombic based technology

For Si and III-V wafers, compatible with non conductive substrates sus as Sapphire, TSV carriers etc.

Electrode Type

Bi-Polar, Multi-Polar.

Heating Elements

Multi zone with integrated temperature measurement

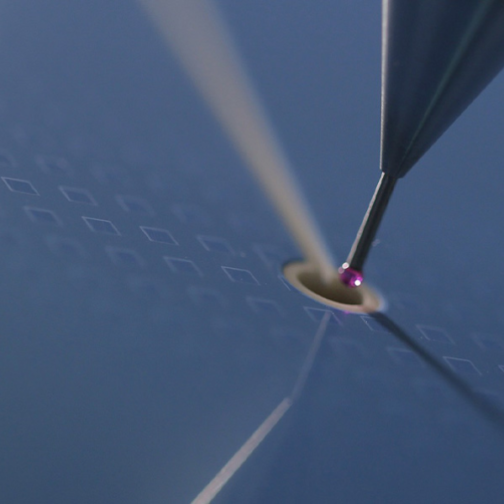

Wafer Contact Surface

Custom Pattern dedicated to customer’s applications.

Products

Our technology

SEMCO Technologies offers reliable solutions for clamping and processing standard, thin and ultra-thin wafers by using proprietary ESC capacitive technology. We also have the ability to manufacture ESC’s that have embedded heaters covering a wide range of temperatures, with perfect homogeneity. SEMCO Technologies offers a complete set of thermal modelling tools for BSG regulation, optimization of thermal transfer and temperature uniformity control with optimized backside particle control.

ESCs

Our expertise.

ESCs are used in various semiconductor processes to hold wafers during processing. ESCs is the single part interfacing the wafer with the tool by creating an electrostatic holding force between the disk and the wafer. ESC and pedestal assemblies are built according to the results of electrical, mechanical and thermal modeling, and on the basis of 100% control through serialization.

Certifications and qualifications

Our certifications

and qualifications.

SEMCO Technologies continously seeks to invest in new manufacturing technologies, research and development and trainings for its teams. We aim at providing the best products and services to our customers and we are commited to meet the highest levels in terms of quality and technicality!

ISO 9001

Project on going – End 2025

COFREND 2

COFREND 2 qualification for leak test calculation

QMOS / CMOS

Employees and equipment QMOS / CMOS certified

ISO 7 Cleanroom

All our products are manufactured in ISO 7 cleanroom

Do you have a question or a project ?

For any additional information, our teams are at your disposal. Do not hesitate to contact us to learn more about our products and services.